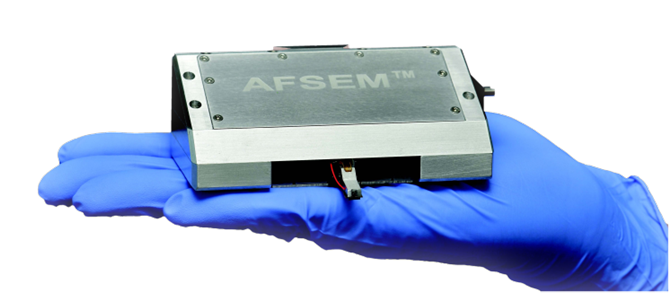

AFSEM® — AFM in-situ SEM

Two microscopes are better than one

GETec Microscopy offers innovative Atomic Force Microscopy solutions for seamless integration into existing host systems like Scanning Electron Microscopes. In partnership with our customers, we develop dedicated nano analysis tools based on pre-engineered modules.

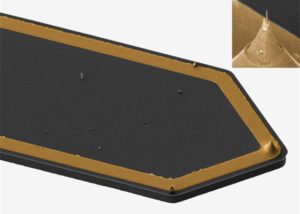

AFSEM® is an AFM by GETec Microscopy, designed for integration into an SEM or Dualbeam (SEM/FIB) microscope. It’s open access design allows to simultaneously operate SEM and AFM inside the SEM vacuum chamber. The complimentary image data of AFM and SEM enable unique characterization of your sample.

What is your Application?

Latest News

Jürgen Schlütter becomes new CEO of GETec Microscopy

We are more than happy to announce that Jürgen Schlütter joins GETec Microscopy as our new CEO.

2019 August, 4-8: Microscopy and Microanalysis meeting in Portland

Meet GETec at the Microscopy and Microanalysis conference in Portland between the 4th and 8th of August. GETec's Stefan Hummel will be present to answer all the questions you might have about AFSEM. Make sure to visit us at the Qunatum Design booth to find out how our product can benefit your application! Find out more...

2019 July, 2-5: 16th Meeting of the French Microscopy Society

GETec will be attending the 16th Meeting of the French Microscopy Society in Poitiers, France. GETec's Pinar Frank will be giving a talk on correlative in-situ analysis by combination of AFM, SEM, and FIB. In addition, it will be the perfect opportunity to learn more about the unique properties of AFSEM. Find out more...

GETec Microscopy Acquisition by Quantum Design International

We proudly announce that we have joined forces with Quantum Design International. “By joining forces, Quantum Design and GETec will significantly increase our combined footprint in the nanotechnology space. GETec’s leading Atomic Force Microscopy in SEM technology nicely complements Quantum Design’s strong position in materials property characterization instrumentation and optics,” stated Jerry Daviess, Chief Executive Officer for Quantum Design International. [...]

AFSEM® users about our product…

“Constantly, applications and challenges arise for which the AFSEM is not only practical, but essential. That starts with direct correlation of specific particles or structures and ends with vacuum conditions as prerequisite, such as thermal measurements. Furthermore, the AFSEM accelerates the work-flow and therefore increases the efficiency for many studies.”

“The high spatial resolution of AFSEM, especially in Z direction, strongly stretched the application of our SEM. Combined with the high angle resolution of EBSD, the AFSEM becomes a powerful tool for the research of phase transformation.”

“What was really convincing to us is the huge versatility of this combination of an Atomic Force Microscope with our excellent optical microscope for our challenging materials and problems. We simply can use real life specimen without big preparation.”

“AFSEM® not only extends the resolution of our microscopes by an order of magnitude, it extends our measurement capabilities beyond topography concerning material composition.”

“Thanks to the AFSEM we can now perform in situ investigations in our FIB microscope, which were not possible before. Especially the possibility to immediately control the result of your nanofabrication experiment is a real benefit!”